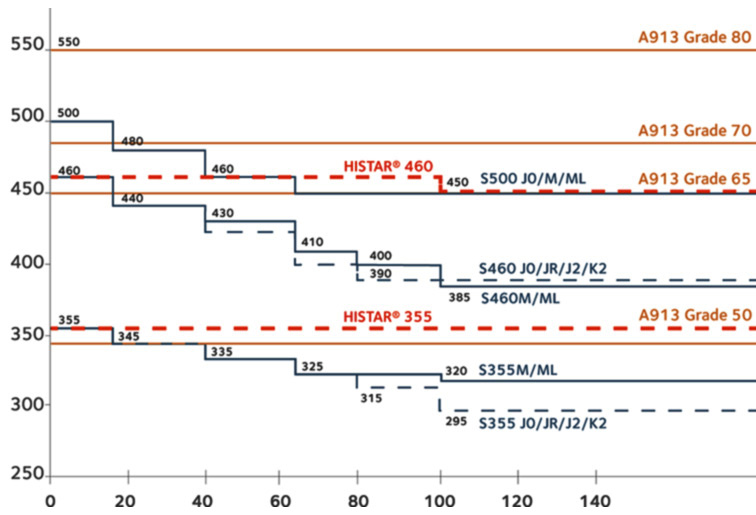

HISTAR® and FRITENAR® are structural steel grades with a low alloy content, combining high strength, good toughness and superior weldability. HISTAR® steels are available in yield strengths of 355 MPa and 460 MPa, FRITENAR® steels are available in 355 MPa.

The application of the innovative in-line heat treatment QST (Quenching and Self-Tempering) allows all HISTAR® grades, unlike most standard grades, to offer improved guaranteed values for yield strength over the whole product range. A comparison between the yield strengths of HISTAR® grades and conventional grades is shown below

| Min. yield strength |  |

| Material thickness (mm) |

HISTAR® steels are delivered in a thermomechanically rolled condition in accordance with the European Technical Approval ETA-10/0156. They comply with the requirements of the European standards EN 10025-4:2019 for weldable fine grain structural steels.

HISTAR® and FRITENAR® steels can be cut with a torch and machined using the process normally applied to structural steel of the same level of strength. Due to the low carbon equivalent, preheating in order to prevent cracking is generally not necessary for product temperatures >0°C.

HISTAR® and FRITENAR® steels offer good weldability for manual and automatic processes, provided the general rules for welding are respected. Due to the low carbon equivalent values of these steels, preheating is not necessary within the range of heat inputs of 10-60 kJ/cm and for temperatures of the structure over 0°C, provided that low hydrogen consumables are used.

For more information on our trademark steel grades, please refer to our dedicated HISTAR® brochure or ask directly to our technical advisory team or your nearest sales contact.

The European standard EN 10027:1992 defines, in combination with the CEN report CR10260, the designation system for steel. The usual symbols for structural steels are shown here.

The following table shows a list of corresponding designations between the European standards as well as the HISTAR® grades with those from the American, Canadian, Chinese and the former national European standards.

The main requirements of the standards regarding the mechanical characteristics and the chemical composition of the available structural steel grades are given hereafter:

- Non-alloy structural steels according to EN 10025-2

- Weldable fine grain structural steels according to EN 10025-4

- Steel grades according to American standards ASTM

- Steel grades according to Russian standards GOST

- Steel grades according to Chinese standards GB/T

Other grades (Japanese or Canadian CSA standards for instance) are available upon request.

The mechanical characteristics of ArcelorMittal's sections are improved by precise control of the temperature during the rolling process. Steels, produced using thermomechanical rolling (delivery condition M), feature improved toughness values thanks to a lower carbon equivalent and a fine microstructure when compared with normalised steels. With regard to their technological properties, the thermomecanically rolled steels have good cold forming properties. Similar to conventional structural steels, they can be flame straightened provided specific maximum temperatures are not exceeded. In case stress relieving is considered for reducing residual stresses, the usual parameters concerning temperature range and heating time according to the rules of practice must be applied. Hot forming, which is however uncommon for the fabrication of sections, must not be performed in accordance with EN 10025:2019.

The steels are typically delivered with a Si content ranging between 0,14% and 0,25%, and are as such capable of forming a zinc layer during hot-dip galvanisation.

As the phosphorus content of these steels is usually lower than 0,035%, it does not have any influence on the final thickness of the coating in the considered Si range.

HISTAR® Offshore and FRITENAR® Offshore are structural steel grades especially developed for offshore applications. In comparison with HISTAR® and FRITENAR® trademark steels, the grades for offshore applications offer the following additional features:

- improved through-thickness deformation properties with respect to the resistance to lamellar tearing (Z qualities);

- notch impact properties in the transverse direction

- maximum ratio between yield strength and tensile strength.

HISTAR® and FRITENAR® Offshore grades are in compliance with EN 10225:2019.

Weldable structural steels for fixed offshore structures according to EN 10225:2019.

Weathering steel grade according to EN 10025-5 / ASTM A588 for sustainable, decorative and cost efficient structures with uncoated steel sections

Arcorox® structural shapes belong to a family of atmospheric corrosion resistant, low alloy steels for sustainable applications with focus on long service life with low maintenance costs.

By initially forming a natural, tightly adherent, protective oxide layer (patina), it strongly reduces further oxidation and thus supersedes the application of any corrosion protection system.

Therefore, along with aesthetic possibilities, Arcorox® provides durable construction even in the absence of initial painting, which enables savings thanks to:

- Reduced construction cost along with construction time;

- Reduced cost of maintenance as well as time of maintenance operation;

- No environmental impact due to absence of maintenance operations and residue.

Esthetically Arcorox uniquely suits to each building: Appearance, texture and maturity of the patina depending on time, degree of exposure and atmospheric environment.

Complete product information available on our leaflet Arcorox.

Mechanical properties and chemical composition of Arcorox.

Steels for elevated service temperatures

Thanks to their improved mechanical properties (specified up to 500°C) and improved creep resistance, 16 Mo3 & P265GH alloyed steel grades are particularly recommended for use at elevated service temperatures.

Those weldable steel grades are particularly relevant for use in powerplant equipment, exhaust systems, hot machine parts or incineration plants.

Delivery condition and production: Following EN 10025 Part 1 and 2 except chemical and mechanical values. Available sections and minimum order quantity are subject to agreement.

Mechanical properties and chemical composition of 16Mo3.