About us

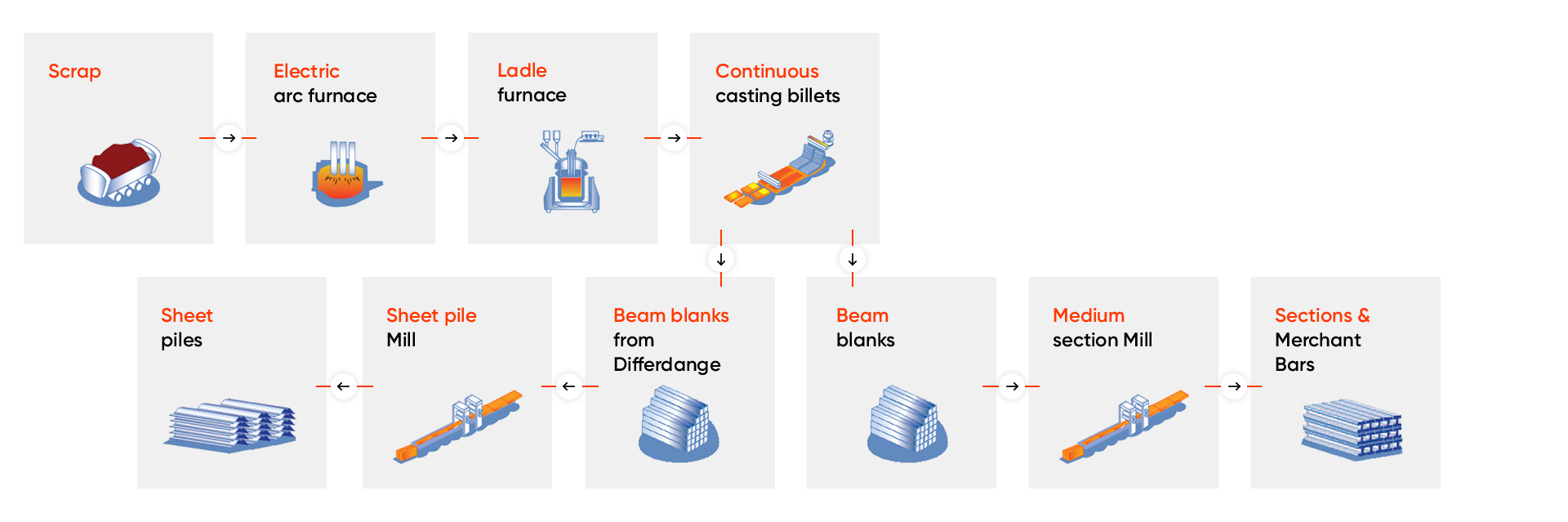

The production site of Belval consists of a melt shop - electric arc furnace, ladle furnace and continuous caster (6 strands) - and 2 hot rolling mills. Raw material for electric steelmaking is 100 % scrap (recycling).

- Sheet pile Mill (rolling mill 2) is specialised in the production of hot rolled sheet piles for all kind of retaining structures.

- Medium section Mill (TMB: tandem mill Belval) rolling mill produces light and medium sections and angles.

Facilities

- melt shop- electric arc furnace

- ladle furnace and continuous caster (6 strands)

- 2 hot rolling mills. Raw material for electric steelmaking is 100 % scrap (recycling).

Finished products

- Columns and Beams: IPE, HE, HD, UB, UC, W

- Bearing piles: HP, UBP

- Channels: UPE

- Angles

Markets

Contact Information

ArcelorMittal Belval

L-4008 Esch/Uelzecht

LUXEMBOURG

How to contact us

Made in Luxembourg

Material Test Certificate

Melt Shop Process

Surface Condition

Surface Corrosion

Copyright pictures: ArcelorMittal