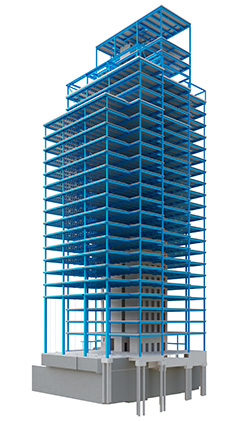

103 Colmore Row, the Birmingham’s tallest office building

When complete, 103 Colmore Row will be Birmingham’s tallest office building. At 26 stories the column elements are the perfect candidate for ArcelorMittal’s HISTAR® 460 HD/UC sections, something that Structural Engineer Davies McGuire was quick to realise.

| Building systems |

ArcelorMittal Solutions | Fire resistance |

||

|---|---|---|---|---|

| Heavies | High strengh steel |

Finished beams |

||

| Columns | internal columns | HISTAR® 460 HD/UC | sprayed/intumescent coating | |

Columns in HISTAR® 460

In the UK, the default steel grade specified in steel design is S355. Specifying ArcelorMittal’s HISTAR® 460 resulted in weight reductions of around 30%, with consequential benefits in cost, but perhaps more importantly embodied carbon reductions of up to 85% were made too. HISTAR® sections are rolled using steel from the Electric Arc Furnace (EAF) at ArcelorMittal’s Differdange mill using scrap steel feedstock. When the embodied carbon savings due to weight reduction are coupled with those from the EAF process embodied carbon reductions of 85% are possible - this is why HISTAR® is one of ArcelorMittal’s Steligence® best in class products.

Advantages of steel construction

The use of clear span cellular beams on 103 Colmore Row facilitated the integration of structure with MEP services allowing the optimal balance of space and height to be achieved. Optimised floor zones reduce building height and so reduce embodied impacts associated with the building envelope, and also minimise air volumes and operational impacts associated with space heating/cooling.

Other benefits include:

The light footprint of a steel frame leads to lighter weight foundations therefore reducing embodied impacts, or facilitates the use of existing foundations getting a second life out of the sub-structure as at 103 Colmore Row

- More flexible office space from a clear span approach thus promoting longevity and supporting circularity

- Faster speed of construction facilitated through offsite fabrication speeding up construction on site

- Reduced cost of ownership

- Higher sustainability ratings

- Lower environmental impact

- Less site traffic during construction through material reduction

Number of Floors: 26 floors

Gross floor area: 22 000m2

Building Function: Office

Structural material: Steel columns and beams with composite floors and a reinforced concrete core

Completion: 2020

Structural Engineer: Davies McGuire

General Contractor: BAM

ArcelorMittal Steel: 2750 tonnes, of which 360t in HISTAR® 460

Fabricator: Severfield NI