High-rise buildings have been built in recent years all around the world and the majority of their structures are built using reinforced concrete as the core and structural steel as the surrounding frame. Minimising the size of the vertical structural elements, without compromising the economic feasibility of projects and limiting their impact on tall buildings’ floor plans, is a constant challenge. The use of composite structural elements combining high grade concrete and steel is a viable solution.

Currently, concrete filled tubes (CFT) or concrete filled continuous caissons built-up by welding heavy plates are common structural solutions. Their main drawbacks include high costs, the need for skilled labour, complex connections, and requiring welding conditions for heavy plates, such as preheating and repairing.

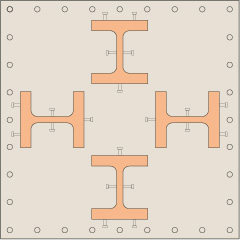

Megacolumns are composed of more than one structural steel wide flange shape with longitudinal rebar and ties embedded in concrete. These are believed to be a convenient solution in terms of structural behaviour, cost and constructability for the design of tall buildings (incl. towers over 300m). They serve to support gravity loads, as well as axial loads from wind and seismic overturning, and the reinforced concrete surrounding the megacolumns is not only for structural stability, but also protects the steel column from corrosion and fire.

This technical solution brings several advantages:

- smaller footprint of the column

- lower prices thanks to the simplicity of the system itself

- safe and reliable (i.e. minimal welding is necessary on site and, fire protection can be achieved utilising the surrounding concrete)

- construction times are decreased dramatically due to off-site fabrication and faster erection

- optimisation of the section using composite action decreases significantly the environmental footprint of the structural system.