The construction of the Sucharski Route was part of the creation and modernisation of Gdańsk’s road system in 2007-2013 in order to connect the city with the national road network (A1 and S7) and part of the project of the European E75 and E77 routes in Poland. Optimisation of the steel structure solution involved collaboration between the general contractor SKANSKA S.A., the design agency EUROPROJEKT Gdańsk S.A and the steel structure supplier ArcelorMittal. 2,040 tonnes of ArcelorMittal's HISTAR® 460 steel was used in the objects.

Replacement project: HISTAR® rolled beams instead of S355 steel welded girders

The WD8 consists of two independent constructions (one for each carriageway. The bridges take the road over railway lines and local roads, and were designed as plain girder VFT (Prefabricated Composite Construction Method) objects in S355 steel grade with slenderness ratios 25-28.

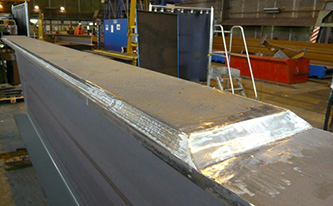

Instead of the S355 steel welded girders, it was decided to use HISTAR® 460 rolled steel beams, which led to the creation of Poland’s first objects using VFT technology with rolled sections in this steel grade. At the same time the WD8, with nearly 400m length, is the longest VFT object in the country. The sections delivered to the construction site were 41m long, eliminating the need for any welding on site. The total amount of welding was reduced by 80%. Using rolled beams ensures a long fatigue life for an object, which is why static schemes in the form of frames or beams from continuous S460 steel is justified from a technical and economic point of view.

The concrete transom solution

In the case of the WD7 and WD8, as with most VFT beam structures in Poland, the contractor decided to construct a prefabricated C40/50 concrete deck onto the steel beams before positioning them in the structure. The innovation in the case of the WD7 and WD8 was the introduction of a staged process of completing the transoms, making temporary propping structures unnecessary.

Once the beams are positioned correctly, with the prefabricated deck forming a lost formwork for the in-situ deck, the concrete for the deck was poured on the slab. This way, the construction of the bridge deck was a simple process completed in 3 stages. First the assembly of the prefabricated slab on top of the beam, which covers around a third of the concrete deck's total height and acts like a formwork for the concrete poured in the second stage. In the third stage, the finishing of the bridge deck was completed in traditional manner.

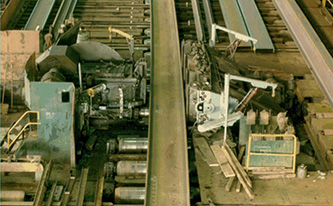

Span construction

The complex prefabricated structures were placed in their intended location using a crane, and their mass reached 50 tonnes. The individual spans were completed in one week on average.

The bridge deck and transoms are made of C35/45 concrete. The span structure was completed in June 2013, and the objects were opened to traffic in October 2013.

Typology: Composite road bridge

Completion: 2013

Design agency: EUROPROJEKT Gdańsk S.A

Contractor: SKANSKA S.A

Steel grade: HISTAR®460

Section size: HL1100

Tonnage: 2040 tonnes

© Gdańskie Inwestycje Komunalne